June 2001

10th June, 2001

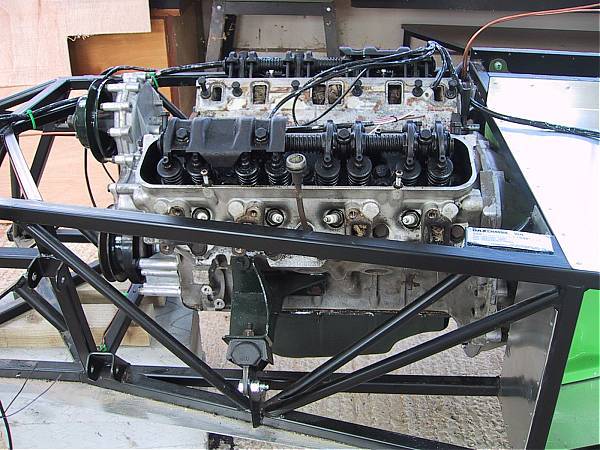

Well eventually the gearbox mountings arrived from Dax and I set about refitting the engine and gearbox (hopefully for good - or until I get round to fitting the 3.9). All went as well as before. Not only that, I also received an additional item destined for William Turner. Hmmm, Dax really need to get their stores operation a little more slick methinks.

Then it was on to fitting the inner footwell GRP panels which again went well although some trimming was required. Finally the battery shelf was fitted, again needing some trimming to fit correctly.

I have yet to source a good supplier of aluminium sheet in my area although there are several hardware stores that will sell a sheet of what can be best described as 'foil' for extortionate amounts of moolah. If anyone one in the West Kent or East Sussex area can name a good supplier, please contact me. This means that I have not yet fabricated the obligatory pedal box cover and so cannot fit the pedal box and steering etc. etc. This is total laziness on my part and really must try to get hold of a large sheet of good quality aluminium.

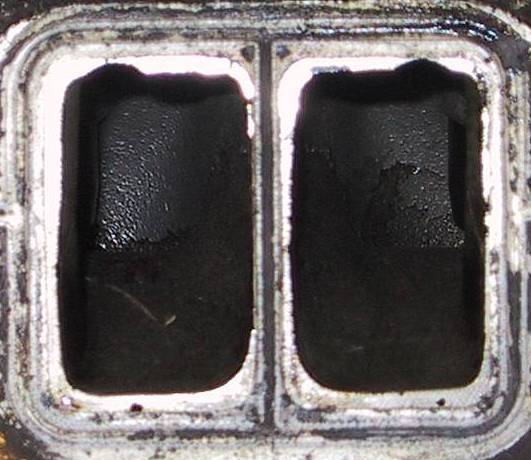

So in lieu of the above, I began to remove the EFI system from my 3.9 discovery engine. This came off reasonably easily and removal of the valley gasket showed a very clean push rod gallery underneath. That being said, the 3.5 engine is 17 years older and that was in almost as good a condition by virtue of the regular servicing. One thing which might cause a problem became clear when I tried to remove the plenum cover. The six M8 x 75mm hex headed bolts would not shift. I wanted to remove the cover to gain easier access to the last manifold bolt. Eventually I managed to undo the manifold bolt with the plenum cover still in situ. The whole assembly is now on the bench with the plenum bolts being soaked in Plus-gas. I suspect that it's the old 'steel bolt in an alloy casting' routine that is causing the difficulty. Although there is little need to remove the cover, it would make installation easier and I'm curious to look inside. What do they say about cats and curiosity......?

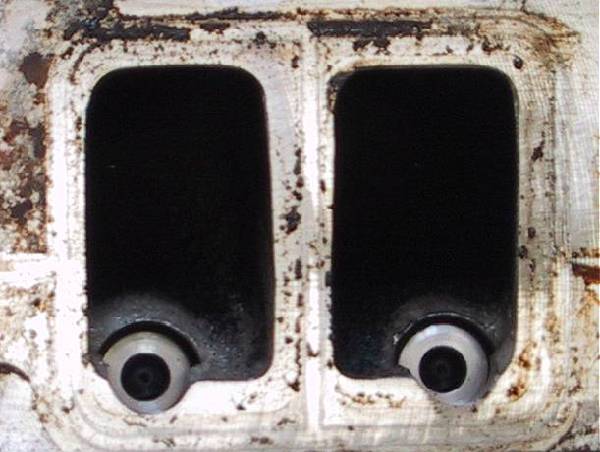

One thing that is now clear is the amount of inlet port grinding I have to do to accommodate the fuel injectors. Each port needs the smallest of semicircular grind to match the similar orifice on the inlet manifold. I don't expect this job to take too long once I have borrowed a Dremmel or similar. Once done, the whole EFI gubbins should just 'bolt straight on'. That remains to be seen however!!

The main thrust of the build at the moment is to get the engine fired up, just to make sure that I'm not completely barking up the wrong tree.

I have been giving some thought to the matter of remote oil filters etc. and was horrified at the price of Rover V8 oil pump covers for the remote pipework to affix to. It would seem that there are two choices, 1) stump up £170 or so hard earned for a kit comprising all the bits based on an oil pump cover or 2) spend £80 or so on a kit using a sandwich plate and blanking plug. This got me thinking and I suddenly remembered that I have already got a sandwich plate that came with the disco engine (they have a remote oil cooler/reservoir ISTR). So by using that all I need to by is the blanking plug, 2x hoses and the remote head. Should save a bob or two if it works (although might not work out much cheaper than option 2 above).

So for next weekend I need to order:-

-

EFI Valley gasket.

-

Oil pump cover gasket.

-

Oil pump cover bolts (mullered them getting them loose).

-

Plenum cover bolts (if the worst happens).

-

Plenum gasket.

-

A Dremmel (if the budget will stretch).

-

Aluminium sheet.

-

And a shed load more 3.5mm rivets.

And, oh yes, I ought to engage the Dax stores operation once again for:-

-

Propshaft.

-

Radiator.

Although depending on research via the list, I might source the last two items elsewhere.

17th June, 2001

Well, for the first time in the build, I managed to get everything I needed to have a full day's graft on the Rush. Rather cowardly, and due to a lack of finance, I didn't call Dax re the above two items instead concentrating on the engine end of things.

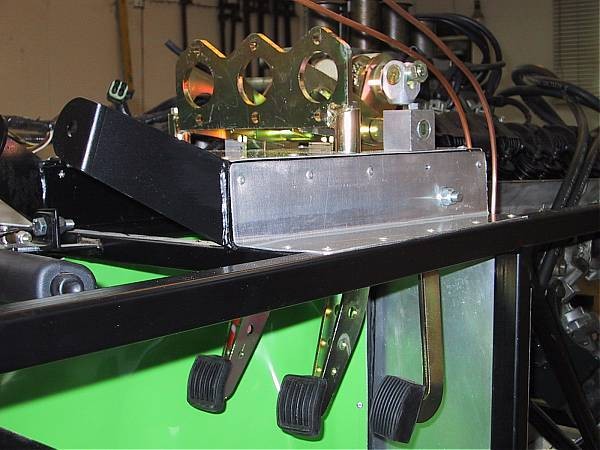

First off, contrary to the above statement re aluminium retailers in Tunbridge Wells, I called the local wholesaler (Spa Aluminium & ONLY 2 miles from my house) who said that he sold large ally sheet offcuts at scrap prices. So, as they are only open office hours, I despatched Dad to buy a sheet. When I arrived at his place today, there was a square metre of 1mm thick ally waiting and all for the grand sum of £9. Reckon that's a good price.

However with my new Dremmel I set about grinding out the inlet ports on the heads to accommodate the fuel injection inlet manifold. This went exceptionally well. The Dremmel was also used to clean up the mating faces (get rid of old gasket sealer etc.) and following that, on went the new valley gasket and induction system. Almost as soon as the manifold was on, it had to come off again. Forgot to remove the rags plugging up the head inlet ports to prevent Dremmel dust falling into the valve guides etc...and that would have made starting the engine interesting! The offending items were removed and the manifold went on again. This time all the bolts were tightened to the correct 25-30 ft/lb. torque.

It then became clear that the plenum cover had to come off to get the nearside rocker cover on. Be warned, those M8 hex head bolts are really tight (and I suspect they are threadlocked). As it had to come off, the jacking handle of my trolley jack was used to 'extend' the Allen key. A large a worrying 'crack' saw the first bolt loosen and the rest soon yielded to the two-foot Allen wrench!

There are very many wires lying around the front of the car now and it looks like the next step is to get the other 'electrickery' mounted and then tie the loom in.

The oil pump was refitted as was the sandwich plate that I mentioned came with the 3.9 engine. I will buy the rest of the bits for the remote oil filter assembly separately rather than a kit.

Finally, I cut and fitted the pedal box 'cover'. Unfortunately, due to the engine now being in, I cannot drill and rivet the front edge how I would like as the engine head gets in the way of the drill. Never mind, Wurth should do the trick. Once the aluminium plate was on, the pedals were dropped into place.

The next jobs are to install the master cylinders and the begin to formalise the wiring at the front of the car. I really need to get the starter motor and solenoid overhauled and get hold of an ignition coil.